Cookware comes in many different shapes, sizes, materials, and applications. All of these factors need to be taken into consideration when selecting cookware for your foodservice establishment. This is because the unique features of a particular piece of cookware are not accidental. They are designed with specific uses and applications in mind. Just as it is important to select the best knife for a specific cutting task, it is just as important to select the piece of cookware that is best suited for the cooking task at hand. There are two main factors we need to consider when it comes to cookware, and those are types and metals.

Types

No matter the shape or size, all cookware may be generally categorized into three types: skillets, saucepans, and stockpots. There are differences and variations within these three types, but most cookware within these three categories will share the same general characteristics.

A skillet is a pan featuring a flat bottom, relatively low, sloped sides, and a long handle which is typically proportional to the diameter of the pan. Skillets are found in common sizes, usually 8, 10, and 12 inches in diameter. Depending on the amount of product you need to cook at one time, you should select the pan size that best accommodates your recipe. Your pan should not be so small that the food is crowding the pan. On the other hand, it should not be so big that there is wasted space, and therefore, wasted heat on the surface of the pan. Skillets are ideal for sautéing, searing, pan-frying, and poaching. A common feature of skillets is a nonstick coating. Visit our Nonstick Coatings blog post for more details on nonstick coatings.

A saucepan is a pan featuring a smaller bottom in comparison to the rim, and flared sides that are higher than that of a skillet. The flared sides allow for easier stirring or whisking. Saucepans also have long handles which are typically proportional to the rim of the pan. They come in a variety of sizes, typically ranging from 2 to 12 quarts. Saucepans are versatile in their application, but they are ideal for cooking, reheating, or simmering smaller quantities of food at lower temperatures. This is especially applicable to liquid-based foods such as stocks, soups, and sauces.

A stockpot is a pot with a thick base and straight, high sides. Stockpots have opposing parallel handles for two-hand carrying. They can be found in various sizes, typically ranging from 12 to 80 quarts. Stockpots are ideal for preparing large batches of soups, stocks, sauces, and stews, or boiling water for cooking large batches of pasta or blanched vegetables.

Metals

Cookware can be found in a variety of metals. The two most common metals used in commercial cookware are aluminum and stainless steel. There are advantages and disadvantages to both.

Aluminum is an excellent conductor of heat. It takes less time to heat to your desired temperature and distributes heat more evenly than stainless steel. More even heat distribution means more evenly cooked food, making aluminum cookware the most popular choice among restaurants. Aluminum is also less expensive than stainless steel.

One disadvantage to aluminum is that it is porous, meaning it can potentially transfer flavors from foods previously cooked in the pan. When cooking with foods that are higher in acidities, such as tomatoes or lemon juice, reactive metals like aluminum can actually leech out into foods, leaving behind a metallic flavor. This could be a potential health concern if you are serving high-risk populations with weaker immune systems such as young children or the elderly. Therefore, you certainly want to consider your recipe when selecting aluminum cookware.

You can find our great selection of aluminum cookware in our store at 3110 Preston Highway in Louisville, KY or online at shop.dinecompany.com. A great example of aluminum cookware would be this 16-quart stockpot from Browne Foodservice which features a durable, high quality 6 gauge aluminum. The thickness of the 6 gauge aluminum allows for even heat distribution, prevention of hot spots, and resistance to warping.

Stainless steel has several advantages over aluminum. First of all, it is non-porous, so it won’t transfer flavors. Second, stainless is non-reactive, making it safe to cook with acidic foods. Third, it is harder and more durable than aluminum, making it more resistant to wear, scratches, and tarnishing. Finally, most stainless steel cookware is induction ready.

The main disadvantage of stainless steel is that it is not the best conductor of heat. It distributes heat slower and less evenly than aluminum. This means that food will not be cooked as evenly. Stainless steel is also more expensive than aluminum.

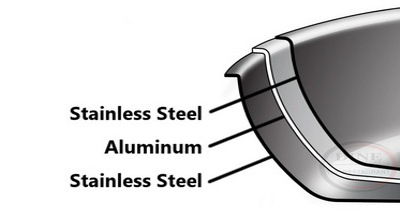

Dine Company also carries a great selection of stainless steel cookware. A great example would be this 6-quart saucepan from Browne Foodservice. It features heavy-duty, stainless steel construction and a hollow cast, stay-cool handle. It is induction capable and also features a 6 millimeter thick, aluminum sandwich bottom. This bottom is a layer of aluminum sandwiched between a layer of stainless steel which is bonded to the pan and allows for increased heat conductivity.

Clad Cookware

With all the advantages and disadvantages of stainless steel and aluminum, wouldn’t it be great if you could combine the advantages of both? This is where clad cookware comes in. Clad cookware is manufactured by using two different types of metals that are layered and seamlessly bonded together during the manufacturing process. The result is a pan that features the desired qualities of both types of metals. For example, you can have an aluminum pan clad with stainless steel that has the superior heat conductivity of aluminum, and at the same time, the non-reactive properties of stainless steel. This is a similar concept to pans with a sandwich bottom, like the saucepan mentioned above, except that the entire pan consists of both types of metals, not just the bottom.

The two most common types of clad cookware are 2-Ply and 3-Ply. 2-Ply pans have one layer of metal bonded to another single layer of metal. For example, this 2-Ply skillet from Browne Foodservice features a bottom layer of aluminum bonded to a top layer of stainless steel. 3-Ply pans have a core of one type of metal layered in between layers of another type of metal. For example, this 3-Ply skillet from Browne Foodservice features an aluminum layer between the top and bottom stainless steel layers.

Extras

Other Metals

Stainless steel and aluminum may be the most commonly used cookware metals, but they are not the only ones out there. Copper is another commonly used metal for cookware. Copper cookware has superior heat conductivity compared to other metals. In terms of even cooking, no other metal performs quite like it. However, it has other properties that are less desirable. Copper is highly reactive to acidic foods, requires high maintenance and frequent polishing, and it is very expensive when compared to aluminum and stainless steel.

Finally, our discussion of cookware metals would not be complete without mentioning cast iron. Cast iron is extremely durable and can last a lifetime with proper care. It is also desirable for its heat retention and even heat distribution. However, it can be reactive under certain conditions and requires extra care to maintain.

Care

In this blog, we have focused primarily on aluminum and stainless steel cookware, as these are the most common types of cookware used in commercial kitchens. For the reasons we have already mentioned, they are simply the most practical and economical types of cookware you can invest in. Yet another reason is that aluminum and stainless steel cookware are relatively low-maintenance and easy to care for. If you follow a few simple guidelines, you can easily increase the longevity and maintain the performance of your industrial cookware.

Perhaps the most important tip to remember is to never immerse any hot cookware in water, whether stainless steel or aluminum. The sudden temperature change can cause warping, which can distort the shape and affect the heat distribution of the pan. Be sure to allow plenty of time for your cookware to cool before you wash it.

When it comes to your aluminum cookware, remember that aluminum is a reactive and porous metal. Because of this, you want to avoid running it through the dish machine. The aluminum can easily react to, or even retain the potentially caustic chemicals your dish machine uses. Another side effect of using the dish machine on aluminum is patina-like discoloration on the surface of the metal. The best practice for your aluminum cookware is to always wash it in your three-compartment sink, using a mild detergent rather than using the dish machine.

Stainless steel cookware is much simpler to take care of. It is dishwasher safe, so there is no need to worry if you choose to run it through your dish machine. However, despite its name, stainless steel can actually develop brown spots and discoloration over time. Just because it is called stainless steel does not mean it can never develop a stain. A more accurate name might be stain-resistant steel. But let’s face it; calling it stain-resistant is not as catchy as simply calling it stainless steel.

No matter how well you take care of your stainless or aluminum cookware, the repeated use and high volume that is typical in commercial kitchens can still often result in grease and carbon buildup on the outside of the pan. Not only is this buildup unsightly and unsanitary, but it can also affect your cookware’s performance. When you are experiencing this kind of extreme buildup on your cookware, there is no better solution than Carbon-Off®. Carbon-Off® is able to remove even the toughest grease and carbon buildup in a matter of minutes. You can find Carbon-Off® in our store at Dine Company, or you can purchase online. You can also click here to see a demonstration of the product in action. You will be amazed at how effective it is!

In conclusion, you should purchase the type of cookware that best suits the individual needs of your own foodservice establishment. Most industrial kitchens today feature diverse menus that require a variety of cookware types and materials. Our hope is that you will be able to apply this product knowledge to select the appropriate cookware for your own specialized menu.