A deep fryer is an absolute staple in commercial kitchens today and regular fryer oil filtration intervals are essential for high-quality food and cost savings. Everyday, people around the world enjoy countless fried foods like chicken, fish, wings, french fries, onion rings, donuts, and hundreds more. As a restaurant owner or operator, you’re likely to have a least one deep fryer in your kitchen, if not several. Are you getting the most out of your fried food program? Are your fryers turning out the best quality product? Are you getting the best return on your investment?

If you don’t filter your oil, both your food quality and your profit margins are suffering. In fact, fryer oil filtration is one of the most important things you can do to preserve the quality of your fried foods and increase your profitability.

Fryer Oil Filtration and Food Quality

How can fryer oil filtration preserve the quality of your food? To answer that question, we need to understand how fryer oil degrades over time during use. The four main causes of oil degradation are water, air, sediment, and heat.

First, water usually finds its way into fryer oil in the form of ice crystals from frozen foods. Some water will also render from food as it cooks, especially if it has excessive marinades. Water is very disruptive to fryer oil due to a lower boiling point.

Second, air degrades oil through oxidation as the oil sits out uncovered when a fryer isn’t being used.

Third, sediment left behind from food particles burn, causing off flavors, odors, and darkening of the oil.

Finally, the heat itself from the fryer degrades the oil quality over time. As the fryer continues to heat the oil, the smoke point of the oil gradually lowers, causing the oil to smoke and deteriorate.

Remember that oil is food too! You can start with the best quality product, but the quality of your food is only as good as the quality of your oil. Burnt, degraded oil imparts bad flavors and aromas into fried foods and it’s less efficient than clean oil. When frying with oil that is past its prime, the breading or the crust on the food does not crisp as quickly causing the food to absorb more oil than usual. Rather than a crispy, golden brown product, you end up with a darkened, greasy mess. The simple equation here is cleaner oil equals better food and better food means more sales.

Fryer Oil Filtration and Cost Savings

Depending on how frequently you use your fryers, fryer oil can easily make up a significant portion of your operation’s overall food cost.

As an example, let’s consider a commercial kitchen that does not filter their oil and has to replace it twice a week. For one fifty-pound fryer, at an oil cost of $1.00 per pound, that equates to $100 a week to operate that fryer. Over the course of a year, that comes out to $5,200, and that’s just for one fryer!

It’s not all bad news and high costs as studies from major commercial fryer manufacturers have proven that the practice of regular, consistent fryer oil filtration intervals reduce the operating cost of a deep fryer by 35% or more. For a restaurant that operates four fifty-pound fryers, using the same numbers, a 35% reduction in operating cost comes out to an annual savings of $7,280!

Restaurants that regularly filter their oil realize these kinds of cost savings because fryer oil filtration extends the life of the oil. With regular to heavy use, oil might last three days at best without filtration. With filtration, you can easily stretch that to an average of six or seven days. As we are all well aware in the restaurant industry, managing your food cost is essential for profitability and, if you operate fryers in your restaurant and you’re not following regular fryer oil filtration intervals, you’re basically throwing money away.

Two Methods of Fryer Oil Filtration

Basic Fryer Oil Filtration

The most basic fryer oil filtration method is a stock pot along with a cone filter and cone filter holder.

Using a stock pot can be tricky because you’ll need one that has a volume capacity greater than the fryer and is short enough to fit under the fryer’s drain valve spout. This can make finding the right stock pot a challenge as most higher capacity stock pots are going to be too tall. That is where a filter pot is very useful, since it has both a large volume capacity along with a low enough clearance to fit under most drain valves.

The filter pot also has the added safety feature of a lid that securely latches in place for safer oil transport. This makes filter pots especially useful for food trucks, as you can store and transport oil in the pot as needed.

Despite the benefits, using a filter pot can still be tedious, as you still must lift the pot and manually pour the oil back into the fry pot in a manner that makes it easy to pour without spilling the oil.

Efficient Fryer Oil Filtration

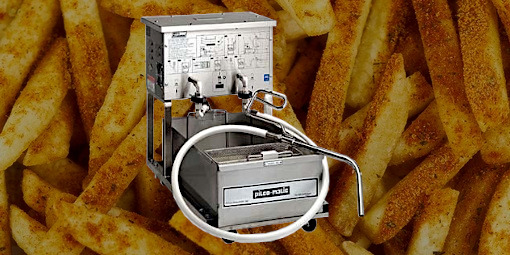

The most efficient way to filter a fryer is by using a mobile fryer filter such as the Pitco P14 or P18.

Mobile fryer filters use a pump to draw fryer oil through filter paper removing impurities from the oil. While the fryer drain valve is still open, pump oil through the hose to dislodge any residual sediment inside the fryer pot. When the fryer is clean, simply close the fryer drain valve, hold the filter hose over the fryer pot, and allow the fryer filter refill the fryer with the filtered oil.

When shopping for a mobile fryer filter, be sure to consider the oil capacity of your fryer and choose a filter that meets or exceeds that capacity.

For greater oil life, add MAGNESOL® powder into your fryer oil filtration process. MAGNESOL® works by extracting dissolved impurities from the oil that the fryer filter alone would not catch. To use MAGNESOL®, simply add the recommended amount on top of the paper fry filter before draining your fryer oil into the mobile fryer filter.

Quick Oil Saving Steps

Regularly filtering your oil is the best thing you can do to get the longest life out of your oil, but there are other ways as well. Here are some simple steps you can follow to extend the life the oil even further.

- Filter the oil at least once per day to get the most quality and longest life cycle. If fryers are heavily used, it’s a good idea to filter at least after every shift.

- Check the oil’s temperature daily to verify set temperatures and calibrate your fryers regularly to prevent oil from overheating.

- Set fryers to 300°F or below when not in use or turn them off when not in use for long periods of time.

- Keep fryer pots covered overnight to reduce oil oxidation.

Regular fryer oil filtration intervals go a long way in producing high-quality food for your customers while saving on expensive oil costs. Whether it’s the basic way with a filter and oil pot or the more efficient way with a portable fryer filter, every foodservice operation should refularly filter their fryer oil. Please use caution around hot oil to avoid burns and spills.

If you have any questions about fryers or oil filtration, give us a call at 502-637-3232 to speak to one of our product specialists. You can also find a full selection of deep fryers, fryer filters, and fryer accessories in our store at 3110 Preston Highway in Louisville, KY.