Beautiful, inviting dining room. Check. Well trained servers, hostesses and bartenders. Check. Menu developed. Check. Food ordered. Check. Line cooks ready to go. Check. Facilities are clean and ServSafe. Check

To the casual observer, this checklist contains the most important things to ensure an enjoyable dining experience. However, to the foodservice veteran, we recognize this list as just the very tip of the iceberg. Below this tip is one of the vast and time-consuming realities of foodservice: food safety.

Foodservice operators and managers are experts at wearing many hats. There is so much to juggle in a single day. A single shift can test the best of your skills. Food safety is a critical part of the day to day operations of a food service establishment. The hourly checks of food and refrigeration temps, rotation of product, the changing of gloves and the red flags for allergens in food prep areas are just to name a few.

There is so much to do and implement that you can get scared and paranoid about the right or wrong way to ensure food safety or you can get busy educating your staff and setting the standard for food safety. It is very easy to let your Hazard Analysis Critical Control Point program go by the wayside. It’s really hard work developing a HACCP program specific to your unique and diverse needs. HACCP is a program used by huge producers of food and pharmaceutical companies to ensure the safe handling, production, and packaging of the product. HACCP has been around for decades and is constantly being tweaked.

A foodservice operator may think a HACCP plan is for larger processing plants or big factories and not able to be implemented on a smaller scale. However, if you look at the principles for which this program was developed it is easy to see that these food safety principles are universal, even if you need to reduce the scope and scale of your own personal program.

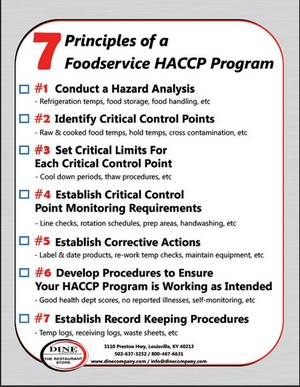

Principle 1: Conduct a hazard analysis. (Refrigeration temps, food storage, food handling…..)

Principle 2: Identify critical control points. (raw and cooked food temps, cold temps, cross-contamination…….)

Principle 3: Establish critical limits for each critical control point. (cool down periods, thaw procedures….)

Principle 4: Establish critical control point monitoring requirements. (line checks, rotation schedule, prep areas, hand washing…..)

Principle 5: Establish corrective actions. (label product, date product, re-work temp checks, maintain equipment….)

Principle 6: Establish procedures for ensuring the HACCP system is working as intended. (good health dept. scores, no reported illnesses, self-monitoring,)

Principle 7: Establish record-keeping procedures. (temp logs, receiving logs, rotation logs, waste sheet……)

If we boil these seven principles down what they really say is: know your product, know its danger zones and know the people monitoring the food safety program.

Dine Company – The Restaurant Store has knowledgeable salespeople and store staff to help you implement a solid food safety plan. We stock everything you will need. Sani-buckets, temp. sticks, mops, three compartment sinks, refrigeration, hot hold boxes, gloves, tongs……EVERYTHING! While food safety can never take a back seat to anything in the day to day operations of your foodservice business, Dine’s staff can help to ease your mind and lead you in the right direction from start to finish in the implementation of your HACCP plan.